062 - 893 5561 | sales@bluetechcontrol.com

062 - 893 5561 | sales@bluetechcontrol.com

BlueTech Control is an expert in providing IoT (Internet of Things) solutions for industrial factories. We leverage modern IoT technology to connect various equipment, such as machinery, sensors, and control systems, helping you monitor and optimize production processes efficiently and transparently.

Our IoT Services

We connect machinery and sensors within the factory to collect data and improve production processes in real-time, enhancing efficiency and reducing operational errors.

Using IoT, we gather data from meters to accurately calculate and bill usage. This enables transparent and efficient cost management within the factory.

Track the status of equipment such as machinery and pipelines through IoT for predictive maintenance, reducing risks and increasing safety.

We install IoT systems to monitor and maintain cathodic protection systems for gas pipelines and metal structures, minimizing the risk of leaks and improving safety.

Why Choose Us?

Case Studies

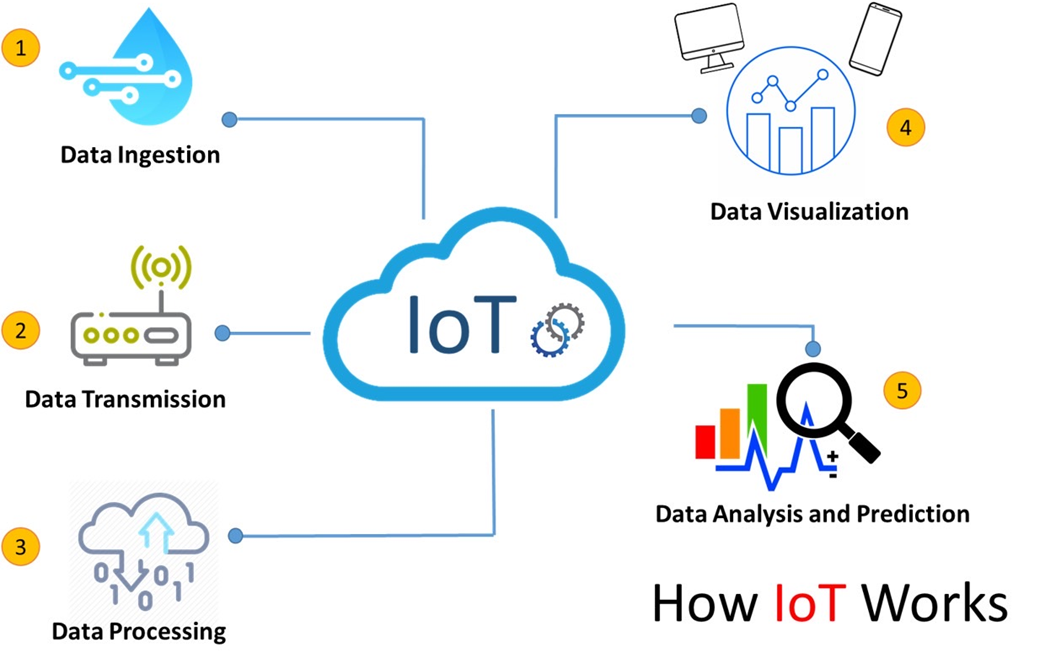

IOT continues to evolve, driving innovation and transforming various aspects of daily life and industry

What Customers Will Gain from Implementing IoT

1. Increased Production Efficiency

2. Real-Time Monitoring & Maintenance

3. Reduced Operational Costs

4. Enhanced Safety & Risk Reduction

5. Accurate Data Collection & Reporting

6. Improved Decision-Making with Real-Time Data

Key Outcomes for Customers

Implementing IoT in industrial operations significantly elevates efficiency, safety, and cost management, helping businesses make better decisions and optimize resources effectively.

ENGINEERING AND SERVICE

PRODUCT

BLUE TECH CONTROL CO.,LTD.

Tel 038-017127 , 062 - 893 5561

Fax 038-017127

e-mail : sales@bluetechcontrol.com